Hot Swap and Marker Test Station

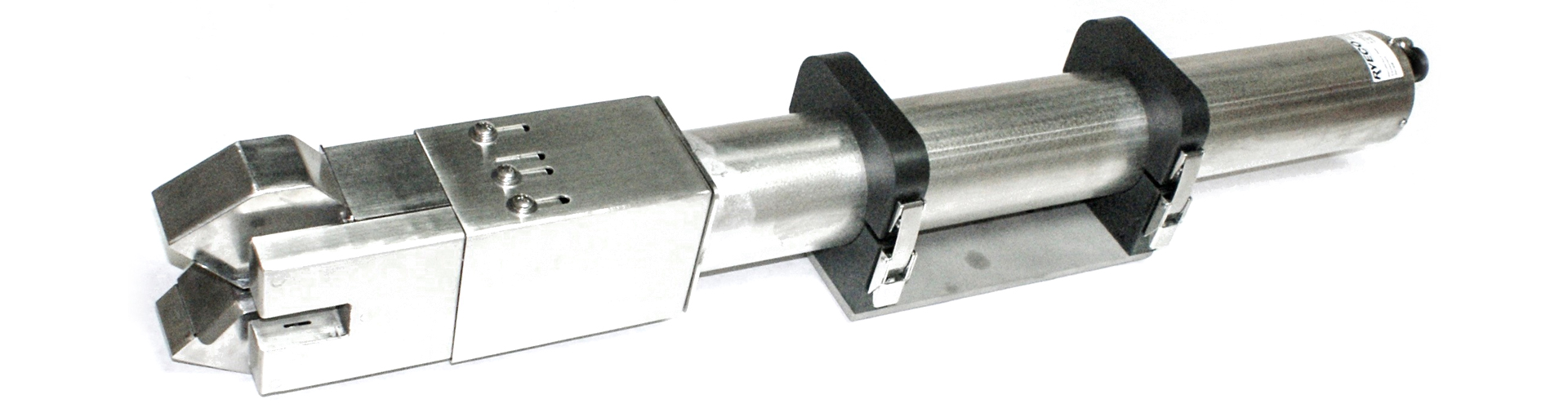

Hot Swap

A Hot Swap consists of a spare Extension Tube, Edge Marking Module and Edge Tracking Module. The entire Marking Assembly is attached to the system’s Actuator Station with two quick-release clamps and can be swapped in less than 1 minute with the existing Marking Assembly. In addition to allowing for a regular maintenance routine, the Hot Swap nearly eliminates the possibility of downtime.

Marker Test Station

The Test Station is a great way to perform periodic Marker maintenance and adjustment in a more convenient setting, away from the production floor.The unit is housed in a small 10.5” x 8.5” x 6.25” (267 mm x 216 mm x 159 mm) cabinet and utilizes a 2-gallon (7.6 liter) water tank to facilitate easy testing and flushing in a workshop setting.

Benefits of a Hot Swap & Marker Test Station

- Allows regular maintenance schedule without taking the Marking System off-line

- Hot swap can be swapped with the existing Marking Assembly in less than 1 minute

- Marker Test Station permits easy marker maintenance & cleaning away from the machine

- Marker operation can be tested in a convenient location off-machine

- A spare Hot swap can be cleaned and ready for use at a moment’s notice