Products

Lane Marking

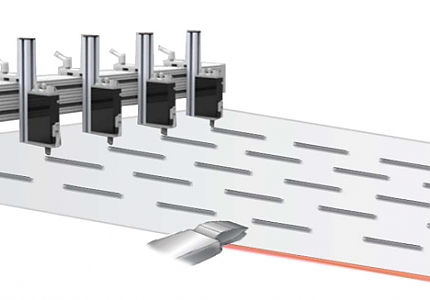

The Ryeco Lane Marking System:

- Sprays 1 color mark on the surface of any web material at any speed.

- Marks can be continuous or pulsed for the length of the defect or as short as 0.5 milliseconds.

- Marks can be visible to the human eye or detected with a Mark Detection System.

- Marks can be invisible and only detectable with a Mark Detection System.

- Marks defects automatically from a Web Inspection System or with process control equipment.

- Operators can manually mark defects via the system's control cabinet, as they occur.

- Maintenance aided with cleaning and flushing capabilities.

Applications

- Defect Marking - The system places marks on a web at a position relative to a defect or process upset.

- Code Marking - The system encodes values onto a moving web.

- Break Marking -The system places a mark on the web after a sheet break is restored.

- End of Roll Marking -The system places a mark on a roll to indicate that the end of the roll is approaching downstream operators and users.

- Registration Marking -The system places marks on a web at precise distance intervals to be used as a registration mark for downstream processes.

- Stripe Marking - The system places continuous or dashed stripes on a web to indicate web orientation or product type.

Industries

- Batteries

- Films, Foils and Plastics

- Nonwovens

- Labels and Narrow Webs

- Packaging

- Lamination and Coating

- Paper and Paper Converting

- Tissue

‹ Back