Products

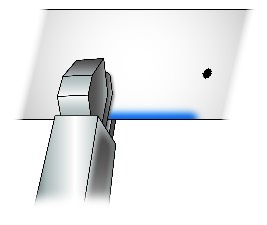

Edge Marking

Defect marking places marks on a web at a position relative to a defect or process upset.

Certain defects in a web will cause problems in subsequent processes. For quality purposes, these defects must be identified and removed prior to shipping to your customers. RYECO's Defect Marker places a colored or invisible mark on the web at the machine direction location of the defect. The system can be used manually by machine operators, interfaces with any Web Inspection System, and can be triggered automatically with any process control equipment. Marked defects warn downstream operators to take preventative actions to avoid downtime and ensure that your customers receive only your best product.

The Ryeco Edge Marking System:

Improve Quality by...

- Marking defects for later removal, ensuring 100% defect-free product.

- Helping eliminate the source of defects by analyzing appearance.

Increase Efficiency by...

- Reducing time spent removing defects; no more guesswork in finding them.

- Reducing downtime from process upsets in downstream processes.

Create a safer work Environment by...

- Reducing injuries caused by cleaning up process errors due to defects.

- Eliminating the dangerous practice of hand-flagging/hand-marking.

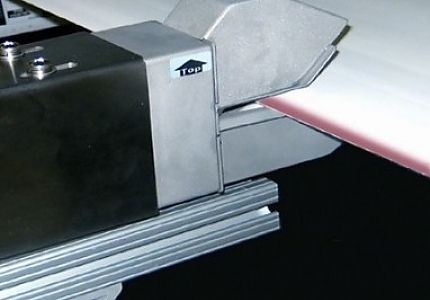

Features of the DEM Defect Edge Marking System

- Sprays up to 3 colors of defect marks on any web material at any speed.

- Marks can be continuous or pulsed for the length of the defect or as short as 0.5 milliseconds.

- Marks can be visible to the human eye or detected with a Mark Detection System.

- Marks can be invisible and only detectable with a Mark Detection System.

- Mark defects automatically from a Web Inspection System or with process control equipment.

- Operators can manually mark defects via the system's control cabinet, as they occur.

- Maintenance aided with cleaning and flushing capabilities.

Applications

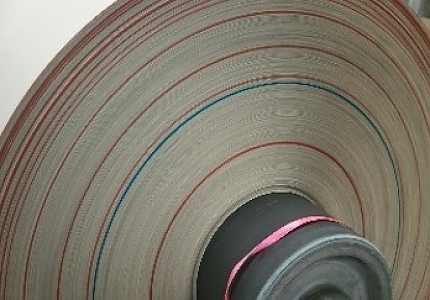

- Defect Marking - The system places marks on a web at a position relative to a defect or process upset.

- Code Marking - The system encodes values onto a moving web.

- Break Marking - The system places a mark on the web after a sheet break is restored.

- End of Roll Marking - The system places a mark on a roll to indicate that the end of the roll is approaching downstream operators and users.

- Registration Marking - The system places marks on a web at precise distance intervals to be used as a registration mark for downstream processes.

- Stripe Marking - The system places continuous or dashed stripes on a web to indicate web orientation or product type.

‹ Back